Safety Signs

Need help?

What is BS EN ISO 7010 and do you comply?

Clear and Compliant Safety Signs from the Market Leader

What is BS EN ISO 7010 and do you comply?

Clear and Compliant Safety Signs from the Market Leader

Looking for safety signs? We’ve got you covered. As market leaders and experts we have every type of sign you can imagine, in a huge range of sizes, materials and designs.

Our signage is UK-approved, ISO-compliant, and made to be durable, eye-catching and effective. We supply innovative signs including photoluminescent, lenticular, vandal-proof, 3D, heavy duty floor signs, and so much more.

Because we incorporate in-house manufacturing, we have what you need and can get it to you with same-day dispatch. Can’t see the sign you need on our site? Check out our DYO (design your own) to custom create exactly the sign you want.

Expert Information

Buying Guide

What is BS EN ISO 7010?

The ISO (International Organisation for Standardisation) 7010 prescribes the shape, colour and graphical symbol required on safety signs. Common symbols (or pictograms) were introduced and tested throughout all European countries to ensure that the symbols were easily understood and recognised. We also keep abreast of any changes to this standardisation to ensure that you are always up to date with the latest safety signs legislation.

Why was BS EN ISO 7010 introduced?

Due to the increased number of non-native speaking workers in each European country, text-based safety instructions were no longer deemed sufficient. This highlighted the same problems facing those with poor eyesight, reading difficulties and other disabilities; the danger to worker safety became much more apparent.

The solution was to create an international standard for safety signs using pictograms that could be easily understood by everyone. This meant that, for instance, a hard hat safety sign in the UK looked exactly the same in another European country.

What you need to do to comply

BS EN ISO 7010 applies to all workplaces, sectors and locations, with the exception of some very specialist signs used in river and maritime, rail, road, and air traffic industries. Any premises required to display safety signs to convey safety information should be using BS EN ISO 7010 compliant symbols.

Who needs to display safety signs?

The Health and Safety (Safety Signs and Signals) Regulations 1996 requires employers to ensure that safety signs are provided and maintained in circumstances where there is a significant risk to health and safety that cannot be controlled or removed by other means.

However, these regulations make it clear that safety signs are not a substitute for other ways of controlling risks to employees. Signs are designed to warn of any remaining risk or to instruct employees of the measures they should take, such as the wearing of foot protection.

You can be sure that your signs comply

We only manufacture signs that comply with BS EN ISO 7010, therefore you can be confident in the knowledge that any sign purchased from us will adhere to the latest legislation – including our custom safety signs.

Safety sign colours and their meaning

Safety signs have a very specific colour coding convention, with each having their own meaning.

Green - safe condition. These include first aid and drinking water signs as well as fire exit signs. Red - prohibition and fire equipment signs. Prohibition signs should be used to show that certain actions must be avoided, such as restricted or no access, no smoking, no dogs. Fire equipment signs should be used to both show the location of fire fighting equipment as well as alarm activation points. Yellow - hazard warning signs. Normally accompanied with the words danger, caution or warning, these signs should be used to provide a clear warning message. Blue - mandatory signs. These instructional signs give clear guidance on what actions must be taken. For instance, the wearing of PPE (personal protective equipment), reporting to reception and keeping a door shut or locked.See our guide to ISO symbols and their meanings for more details.

As market leaders in Safety Signs we have the expertise and manufacturing capabilities to create the signs that you need that are compliant and always of the highest quality. Safety is made easy with Seton.

For more information, please check out this short video:

FAQs

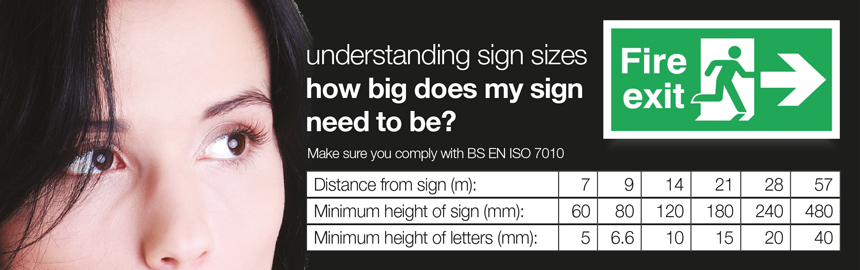

What size sign do I need?

The size of a safety sign is dependent on its location, the size of font used and, to a certain degree, its position.

Your sign should always be displayed where it can be easily seen from various locations. Use the below guide to help you decide on the correct size of sign.

If you have staff or visitors with impaired vision, then consider using both standard and Braille safety signs.

What if there is a power failure, will my sign be seen in the dark?

Unless there is emergency lighting or a source of natural light, then the honest answer is probably no. However, one quick and easy solution would be the installation of photoluminescent the installation of signs that are designed to be seen in the dark. They do not require any special maintenance or specialist equipment and will glow in the dark.

There are a lot of sign materials to choose from; which is best for me?

There are a couple of questions you need to ask yourself:

Is the sign going to be displayed indoors or outdoors?

Do I want a standard sign that conveys my safety message or do I want a more prestigious look?

The majority of materials are suitable for use both indoors and out, including our most popular ones – self-adhesive vinyl, rigid plastic and adhesive rigid plastic.

Self-Adhesive vinyl is quick and easy to apply with the minimum of fuss. Simply peel off the protective backing strip and stick where needed. Vinyl is flexible and is therefore ideal for adhering to curved or slightly uneven surfaces.

Adhesive rigid plastic is solid but again with a self-adhesive backing for fuss-free application. These signs are ideal for use on smooth surfaces.

Rigid plastic signs require drill holes or the use of a permanent adhesive. Drill holes can be added at the time of manufacture for a minimum cost - please call one of our sales team for more information.

Our handy signs material guide provides more information on each material available, including aluminium and acrylic for when a more prestigious look is required.

What if you don’t have the sign I need?

We have a huge range of signs in stock, created by our team of in-house experts. You can also design and create your own Custom Safety Signs quickly and easily and get guaranteed fast delivery times.

Why are safety signs necessary in the workplace?

Wherever there are potential hazards, safety signage in the workplace is essential to warn staff of dangers and to raise safety awareness generally.

Health and safety signs and symbols play an important role in communicating vital information in a visible and easily understood method.

Safety symbols and pictograms are a universally understood format, which makes worksite safety signs extremely effective in minimising accidents and injuries to staff and visitors.

What Are the Different Types of Safety Signs?

Prohibition (Red circle with a red diagonal line through it)

Prohibition signage is used to limit the risk of accidents by indicating, for example, areas where smoking is prohibited and where flames are prohibited. Prohibition signs also can indicate areas where access is prohibited for unauthorized persons. Seton has a wide selection of prohibition signs.

> View our Prohibition Signs

Mandatory (Blue circle with white symbol)

Information and mandatory signs are used to minimize risks to employees health and safety. This sign is useful for communicating information and imposing safety rules for example: to remember to wear personal protective equipment (PPE).

> View our Safety Clothing (PPE) Signs

Danger (Yellow triangle with black symbol)

Some activities involve exposure to significant hazards such as electricity, high temperatures, machinery, sheer drop or even explosion. Danger signs are essential in order to warn and protect employees, visitors and the general public.

> View our Danger Signs

Fire (Red rectangle/square with white symbol)

Fire safety signs are vital in order to facilitate the response of firefighters and emergency crews in the event of a fire. Fire safety signs indicate where to find fire-fighting equipment such as fire extinguishers as well as the location of fire alarms.

> View our Fire Safety Signs

Evacuation (Green rectangle/square with white pictogram/text)

Fire Exit Signage is essential to maintain the safety of people present in your premises including staff and visitors. Refuge point signs, evacuation signs / fire exit signs and fire assembly point signs are crucial to facilitate the emergency services and to guide personnel in the event of an emergency evacuation.

> View our Fire Exit Signs

First Aid (Green rectangle/square with white symbol/text)

First Aid signs are essential to inform and guide staff and visitors in case of an emergency situation. First aid signage makes it possible to quickly locate first aid kits and other first aid equipment, including defibrillators and emergency facilities.

> View our First Aid Signs

Harmful Substances (Red diamond with black pictogram/symbol)

Harmful Substances signs are for anyone who comes into contact with chemicals and/or dangerous substances. Their purpose is to warn any personnel, and to specify the nature of the danger, so that appropriate caution can be taken in order to reduce any potential risk. Seton offers a range of signs dedicated to dangerous products and substances to advise of the proximity of flammable materials, irritants or substances that are dangerous for the environment. See also our selection of signs for harmful, corrosive or radioactive materials.

> View our Harmful Substances Signs

Information (Blue lower-case 'i')

Whether installed inside or outside your premises, information signs help staff and visitors with guidance on a variety of things. Information signs can be used to indicate reserved car park spaces, the location of washroom facilities or the presence of surveillance cameras.

> View our Information Signs

Recycling Signs (Mobius loop recycling symbol)

Recycling Signs encourage employees to take responsibility for and pay attention to the recycling of paper, plastic and other recyclable materials. The signs indicate the contents of each bin and best practice in terms of separating materials into the appropriate containers. Seton offers a wide selection of recycling signs and labels.

> View our Recycling Signs

Accessibility (Blue rectangle/square with white stylised pictogram of person in a wheelchair)

Workplaces that provide accessibility to people with disabilities often require special planning. Accessibility signs can indicate parking spaces, toilets, lifts or wheelchair ramps. Braille and tactile safety signs for the visually impaired and hearing loop symbol signs for the hearing impaired are amongst the special signage available from Seton.

> View our Accessibility Signs

What size sign should you choose?

Make sure that your signs are large enough to be read and understood even from a distance. Place your signs in a strategic location so that staff and visitors can see the sign before entering the zone concerned. For example, a sign indicating a compulsory wearing of safety clothing should be displayed before the appropriate zone, not inside the zone.

Recommended size formats for good visibility of signs.

Seton offers you various sizes for more visibility. Choose the size of your safety signs according to location and distance.