-

Promotion

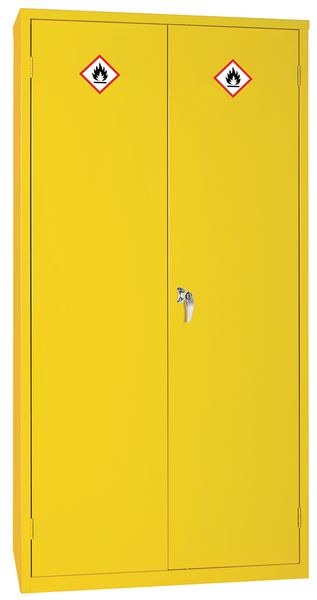

Dangerous & Flammable Substance COSHH Storage Cabinets

From £249.99 To £549.99

From £199.99 To £519.99

Supplied in: Single -

Promotion

COSHH Grey Chemical Storage Cabinets with GHS labels

From £219.99 To £519.99

From £209.99 To £519.99

Supplied in: Single -

Promotion

Mini Dangerous & Flammable Substance COSHH Storage Cabinets

From £199.99 To £279.99

From £199.99 To £269.99

Supplied in: Single -

Promotion

Chemical Storage Vaults

From £999.99 To £1,599.99

From £899.99 To £1,399.99

Supplied in: Single -

Promotion

Dangerous & Flammable Stackable Substance Storage Cabinets

From £349.99 To £359.99

From £329.99 To £349.99

Supplied in: Single -

Promotion

COSHH Cabinet Stands

From £119.99 To £149.99

From £99.99 To £119.99

Supplied in: Single -

Promotion

Flammable & Chemical Storage Vaults

From £549.99 To £4,999.99

From £549.99 To £4,499.99

Supplied in: Single kit -

Flammable Storage Boxes

From £239.99 To £629.99Supplied in: Single -

Promotion

Armorgard FlamStor COSHH Flammable Storage Cabinets

From £699.99 To £4,699.99

From £649.99 To £3,999.00

Supplied in: Single -

Promotion

Corrosive Cabinets

From £259.99 To £599.99

From £259.99 To £578.24

Supplied in: Single -

Promotion

Dangerous/Flammable Substance Storage Bins

From £349.99 To £649.99

From £289.99 To £499.99

Supplied in: Single -

Armorgard Chemcube COSHH Storage Cupboards

From £699.99 To £1,699.99Supplied in: Single -

Promotion

Fire Resistant Safety Cabinet 30

£2,299.99

£1,999.99

Supplied in: Single -

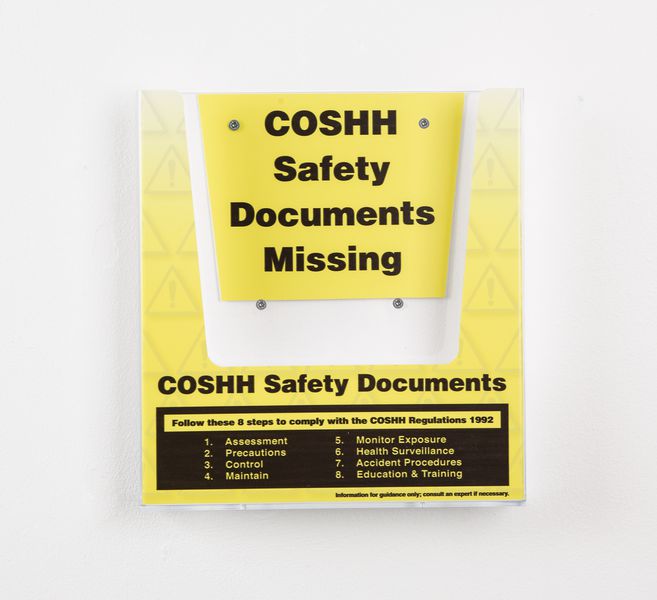

COSHH Safety Document Holder

From £19.99 To £34.99Supplied in: Single -

Promotion

Galvanised Drip Trays

£69.99

£64.99

Supplied in: Single -

Promotion

Flammable Liquid Plunger Cans

From £89.99 To £99.99

From £64.99 To £79.99

Supplied in: Single -

Promotion

Wall-Mount Flammable Liquid Storage Cabinets

From £279.99 To £299.99

From £239.99 To £249.99

Supplied in: Single -

Promotion

Armorgard Gorilla Gas Cage Cylinder Storage

From £599.99 To £2,999.99

From £549.99 To £2,899.99

Supplied in: Single -

Promotion

Extra Shelf for Flammable Liquid Storage Cabinets

From £34.99 To £39.99

From £26.99 To £39.99

Supplied in: Single -

Promotion

Foot Operated Steel Oily Waste Can

From £129.99 To £249.99

From £99.99 To £169.99

Supplied in: Single -

Promotion

Armorgard TransBank Chemical Storage Box

From £249.99 To £469.99

From £229.99 To £469.99

Supplied in: Single -

Promotion

Fire Resistant Safety Cabinet 90

£3,999.99

£3,599.99

Supplied in: Single -

Promotion

Armorgard DrumCage Storage Cage

£2,499.99

£2,399.99

Supplied in: Single -

Promotion

JUSTRITE® Flammable Storage Cabinets

From £499.99 To £2,199.99Supplied in: Single -

Promotion

Justrite Flammable Liquid Dip Tank Cans

From £149.99 To £169.99

From £129.99 To £149.99

Supplied in: Single -

Promotion

Flammable Liquid Type II Dispensing Can

From £149.99 To £159.99

From £119.99 To £149.99

Supplied in: Single -

Customisable

Customisable

Chemical Storage Cabinet Stand

£129.99Supplied in: Single -

Promotion

COSHH Pesticide & Agrochemical Cabinets

From £269.99 To £899.99

From £249.99 To £799.99

Supplied in: Single -

Promotion

Fire Resistant Cabinet with Safety Box

£2,299.99

£2,099.99

Supplied in: Single -

Promotion

Steel Jerry Can Pouring Spout

£14.99

£13.99

Supplied in: Single -

Promotion

Flame Store

£499.99

£449.99

Supplied in: Single -

Promotion

Master Safety Data Sheets Holder

£19.99

£17.99

Supplied in: Single -

Promotion

COSHH Cabinets - Extra Shelves

£34.99

From £24.99 To £34.99

Supplied in: Single -

Promotion

Justrite Flammable Liquid Bench Cans

£99.99

From £74.99 To £79.99

Supplied in: Single -

Promotion

Galvanised Bins

From £399.99 To £429.99

From £369.99 To £429.99

Supplied in: Single -

Promotion

Dangerous & Flammable Substance Cabinet - Sloping Top

£89.99

£79.99

Supplied in: Single -

Fire Resistant Cabinet Extraction Unit

£799.99Supplied in: Single -

Promotion

Justrite Flammable Liquid Laboratory Can With Spout

£229.99

£159.99

Supplied in: Single -

Promotion

Steel Jerry Single Can 10L Capacity - UN Approved

£39.99

£34.99

Supplied in: Single -

Customisable

Customisable

Acid (Corrosives) Cabinet Stand

£129.99Supplied in: Single -

Promotion

GHS Safety Document Holder

From £19.99 To £34.99

From £19.99 To £29.99

Supplied in: Single kit -

Promotion

Armorgard Forma-Stor COSHH Cabinet

From £4,099.99 To £6,499.99

From £4,099.99 To £5,999.99

Supplied in: Single -

Promotion

COSHH Pesticide & Agrochemical Cabinet Stands

From £289.99 To £299.99

From £169.99 To £189.99

Supplied in: Single -

Air Filter System

£1,999.99Supplied in: Single -

Promotion

Fire Resistant Underbench Safety Cabinet

£2,799.99

£2,599.99

Supplied in: Single

Chemical Handling & Storage

Need help?

Learn how to handle chemicals safely

Top-Rated UK Compliant Chemical Storage & Handling Equipment

Learn how to handle chemicals safely

Top-Rated UK Compliant Chemical Storage & Handling Equipment

Regular usage of chemicals and hazardous substances can be used in the workplace, and carrying out measures for approved management is key in reducing potential risk of harm or occupational health issues to workers, according to COSHH Regulations 2002.

By using COSHH storage, such as a chemical cupboard, they are used specifically for chemical management, organisation and support with secure access of hazardous substances or liquids. Using chemical containers, and accessories can also benefit to assist with safe usage of hazardous substances.

Each item is handpicked by Health and Safety Experts in order to improve workplace safety and productivity. We guarantee high-quality products which are highly rated by our customers.

Expert Information

Chemical Handling & Storage: Buying Guide

What is chemical handling?

Regular usage of chemicals and hazardous substances can be used in the workplace, and carrying out measures for approved management is key in reducing potential risk of harm or occupational health issues to workers, according to COSHH Regulations 2002.

By using coshh storage, such as a COSHH cabinet or chemical cupboards, they are used specifically for chemical management, organisation and support with secure access of hazardous substances or liquids. Using chemical containers, and accessories can also benefit to assist with safe usage of hazardous substances.

Each item is handpicked by Health and Safety Experts in order to improve workplace safety and productivity. We guarantee high-quality products which are highly rated by our customers.

Chemical handling refers to any activity where employees, contractors or other people working on your premises have to carry out activities that require them to work with, supply, transport or transfer chemicals. It is important to provide training and advice for anyone who falls into this category, regardless of whether they are expected to have any direct contact with hazardous objects.

Working with hazardous substances of any type can be extremely dangerous and has the potential to pose the following hazards:

Health

Without sufficient control methods anyone who comes into contact with chemicals can be at risk of illness, injury or death.

Premises

Inadequate store facilities can cause chemicals to become unstable, increasing the chance of explosions or other emergency situations.

Environment

Poor treatment practices can lead to spillages and accidental contamination of your surroundings.

By using the appropriate control processes, facilities and equipment, the possibility of any of these occurrences can be minimised.

Storing Chemicals Safely

When deciding where and how to store substances or liquids, there are several factors that should be taken into account. First you should define a specific area where access can be controlled. It must be an appropriate distance away from where you work, but also close enough to prevent the excessive transportation of materials. Ensure that the space is well-lit and sized appropriately to safely store everything, taking into account the need to separate certain types. Ventilation is also incredibly important, even when items are stored within a cabinet, as vapours can easily build up over time. We offer an Air Filter System which recirculates air, capturing harmful solvent (hydrocarbon) vapours.

How and where you keep chemicals within your workplace is governed by strict rules. For example, the amount of flammable liquid that can be stored in one place will vary according to its flashpoint; additionally, certain different types must be segregated from each other on a different level. Looking at these factors should play a major role in determining what provisions you need to securely store your items. Our helpful Legislation Watch article has more information on how to store harmful substances or liquids safely.

When setting up the storage area pay particular attention to signage. Storage should always be clearly marked using Globally Harmonized System of Classification and Labelling of Chemicals (GHS) symbols so that staff are instantly aware of what can and can’t be held safely in a particular location. Information posters and notices should also be placed nearby.

Purpose-built COSHH cupboards and cabinets are the best course to ensure day to day amounts of harmful substances are securely stored. All units of this type should be lockable – ideally with 3 point locking, constructed from flameproof material and be able to contain leaks and spills at ground level amounting to at least 110% of the largest vessel kept within.

Keeping storeroom areas clean and tidy is vital to their ongoing safety. Any waste packaging such as cardboard boxes or plastic wrap should be disposed of away from the store room site to minimise the risk of fire. Ensure you have adequate spill control resources such as absorbent materials and drain covers nearby to deal with spills and leaks.

Safe Handling of Chemicals

Containers for moving or working with small amounts of harmful liquids should be expressly constructed for their intended purpose. Never reuse a bottle or canister that was designed to be disposable and keep a different container for each item that will be transported to prevent cross-contamination. Particular care should be taken to ensure flammable liquids are transported in suitable vessels.

Finally, once you have your storage and controlling areas organised be sure to conduct weekly checks on not just the equipment, but also how staff are storing hazardous items to ensure best practice is being observed.

FAQs

I don’t work in the chemicals industry, am I likely to have any items that would be covered by COSHH regulations?

Of course, this can be a possibility. However Very, very few businesses get by these days without using chemicals of some sort. As well as more obvious industries such as farming or painting and decorating, chemicals can be found everywhere from warehouses and car parks to shops and schools. Depending on your situation, one of the most likely types of chemical you will be dealing with on a regular basis is cleaning products. Even if you only use a small amount they should be kept locked away and stored in trays which will catch any leaks. You will also need to observe rules regarding storing incompatible substances together and take extra caution over flammable items. Small scale cabinets are perfect for this. For more information, view our working safely with corrosive substances guide

How do I assess what storage I need for the chemicals I have?

Suppliers of chemicals or chemical items will be able to provide you with a safety data sheet for every item you purchase. Use this to decide what storage provision you need. For many, a COSHH cabinet or cabinets will be enough; for larger amounts, outside store rooms (such as bins) may also be required. If you use and store substances in drums or cylinders, specific solutions are available for their management to minimise any associated risks. If you require further assistance in determining exactly what you need, our helpful “Ask the Expert” service can offer advice and guidance. We do offer a useful Master Safety Data Sheets Holder, which are easy to view when needed, and supports COSHH management in the workplace.

What are safe ways of handling chemicals?

Each chemical that is used within your business should have a specific procedure for safe usage, which will depend on the nature and strength of the substance. Appropriate procedures must be made clear to all workers who are involved in substance storage and usage, and proper training should be provided to ensure that everyone involved uses all possible precautions to avoid: spillage, leakage, exposure, or other hazards when using, transporting and storing chemicals. All workers exposed to dangerous substances should wear appropriate personal protective equipment (PPE), be well trained in the practice of disposing of chemicals safely, and be prepared for chemical-related accidents, or in a health-related emergency, with appropriate first aid training.

What are chemical handling dos and don’ts?

While in-depth training on specific harmful substances and liquids is vital if your employees regularly work with harmful items, there are some general dos and don’ts regarding chemical usage and the storage of hazardous substances or liquids that everyone should be aware of.

Do:

- Read product labels carefully and follow the manufacturer’s directions and recommendations regarding the appropriate usage and storage of any harmful product, including what to do if accidental exposure occurs.

- Store hazardous substances appropriately. Use designated chemical containers, and a chemical cabinet or hazardous cupboard if appropriate.

- Keep chemical stores in a dry, well-ventilated area, where air is supplied and ensure that appropriate signage in the chemical storage area indicates the potentially hazardous nature of the products.

- Use appropriate Personal Protective Equipment (PPE) when dealing with hazardous substances or liquids.

- Clean up spills promptly and safely, according to the manufacturer’s instructions and best practices.

- Know the correct first aid procedures for chemical burns and other accidents involving chemicals, such as accidental inhalation and skin or eye exposure.

- Dispose of chemicals and waste goods safely.

Don't:

- Work with toxic or hazardous substances or liquids alone.

- Store chemicals near petrol, fire hazards, or other chemicals with which they could interact, and could cause a fire ,explosion, or personal injury.

- Smoke near hazardous store rooms or areas which may contain hazardous items.

- Inhale fumes from chemical substances. Inhaling small amounts on a regular basis can be toxic, and highly hazardous to long-term health.

- Mix two or more products in the same container when disposing of unused products and toxic waste.

What are the necessary precautions when handling chemicals?

As already mentioned, one important precaution is PPE equipment, especially within environments that will give off toxic or hazardous fumes, employees or visitors may benefit from the usage of respiratory protection, eye protection (such as safety glasses or safety goggles), and protective clothing which will enable them to stay safe in the workplace. It is vital to ensure that first aid and safety equipment, such as eye wash stations and safety showers are also available near chemical storage and operating areas, and in any situation or emergency where substance usage poses a risk of injury to employees. Chemical burns are a particularly nasty injury and it is vital to protect employees.

It is also necessary to ensure that staff are fully trained in first aid and safety procedures relevant to the handling and containment of substances, and can deal promptly and efficiently with accidents, spillages, chemical fires and other health and safety risks. We also recommend using correct signage to make others aware of hazardous and toxic substances, or liquids, for example, our Danger Toxic Hazard Signs can be positioned as required to warn visitors and employees of potential hazards around the workplace.

Which chemical handling and storage solutions does my business need?

| JUSTRITE® Flammable Storage Cabinets | |

|---|---|

|

Lockable metal cabinets with heavy-duty, 3-point locking doors, fully welded construction, and a self-closing mechanism to ensure that doors shut and latch from any open position - perfect in busy locations or emergencies. Dual wall construction provides 38mm of insulating air space, keeping the internal temperature of the cabinet as low as possible. |

|

Shop now |

| Dangerous/Flammable Substance Storage Bins | |

|---|---|

|

These Storage Bins act as mini chemical cabinet which sits at floor level. They are constructed from 20-gauge mild steel with a durable, epoxy polyester, powder-coated finish and are clearly labelled with "Highly Flammable" hazard warning diamonds. These come in a variety of sizes to suit your containment needs. In addition, the height makes items easy to reach. |

|

Shop now |

| Master Safety Data Sheets Holder | |

|---|---|

|

This data sheets holder ensures that the appropriate documents are kept close at hand and clearly displayed. Ideal for storing and dispensing any onsite A4 or A5 documents, and helps to comply with COSHH guidelines. |

|

Shop now |

| Dangerous & Flammable Substance COSHH Storage Cabinets | |

|---|---|

|

Secure and highly visible large cabinet to store chemicals, paints, flammable materials and hazardous substances. The shelves are adjustable to accommodate storage of different sized containers, allowing to view and reach items safely. |

|

Shop now |

Ultimately, your needs will depend on your circumstances and the results of your company’s risk assessment. Here at Seton, we have 100’s of Chemical management and COSHH Safety tips to protect your employees and working environment. As well as help you and your business plan and maintain the best course of action stay within the law. View them here in our What is COSHH and How to do a COSHH Assessment guides. Get in touch with our friendly experts if you have any questions.