-

Scafftag® Laddertag® Replacement Holders

£57.99Supplied in: Pack of 10 -

Scafftag® Laddertag® Inserts

From £17.54 To £87.64Supplied in: Pack of 50 -

Scafftag® Laddertag® Kit

From £8.99 To £51.99Supplied in: Single kit -

Scafftag® Multitag Kit

£50.99Supplied in: Pack of 10 -

Scafftag® Laddertag® Complete Kit

£99.99Supplied in: Single kit -

Scafftag® Replacement Holders

£50.99Supplied in: Pack of 10 -

Forkliftag® Inspection Booklet

£13.99Supplied in: Single -

Multitag® Inserts

From £17.99 To £86.39Supplied in: Pack of 50 -

Scafftag® Permit Wallets

From £10.99 To £71.99Supplied in: Pack of 10 -

Laddertag Kit with Extra Inserts Bundle

£187.99Supplied in: Single kit -

Laddertag & Safety System Kit

£83.99Supplied in: Single kit -

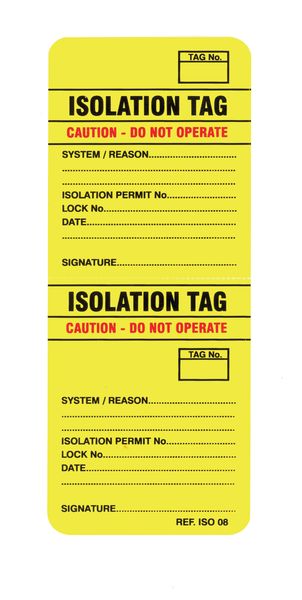

Scafftag® 2-Part Isotag®

From £13.99 To £56.99Supplied in: Pack of 50 -

Scafftag® - Workers Emergency ID Tags

£7.99Supplied in: Single -

Scafftag® Microtag Holders

From £38.99 To £50.99Supplied in: Pack of 20 -

Scafftag® Unitag® Kit

From £52.99 To £74.99Supplied in: Pack of 20 -

Scafftag® Unitag® Inserts

From £8.99 To £42.99Supplied in: Pack of 20 -

Scafftag® Microtag® Kits

From £29.99 To £64.99Supplied in: Single kit -

Scafftag® Forkliftag Kits

From £20.99 To £76.99Supplied in: Single kit -

Scafftag Forkliftags Replacement Inserts

From £10.99 To £125.99Supplied in: Pack of 50 -

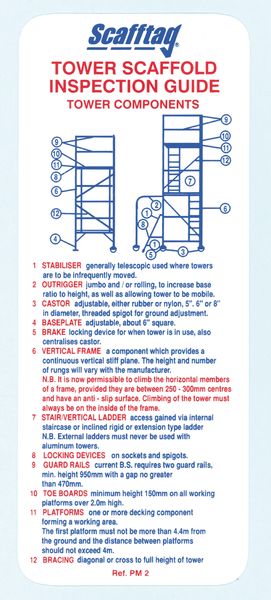

Scafftag® Towertag® Replacement Insert

From £9.99 To £61.99Supplied in: Pack of 10 -

Scafftag® Standard Inspection Inserts

From £18.99 To £61.99Supplied in: Pack of 50 -

Scafftag® Towertag® Kits

From £5.99 To £66.99Supplied in: Single kit -

Scafftag® Towertag® Replacement Holders

£50.99Supplied in: Pack of 10 -

Scafftag® ID Tags

From £0.99 To £1.99Supplied in: Single -

Scafftag® Microtag Inserts - Vibration Control

£19.99Supplied in: Pack of 20 -

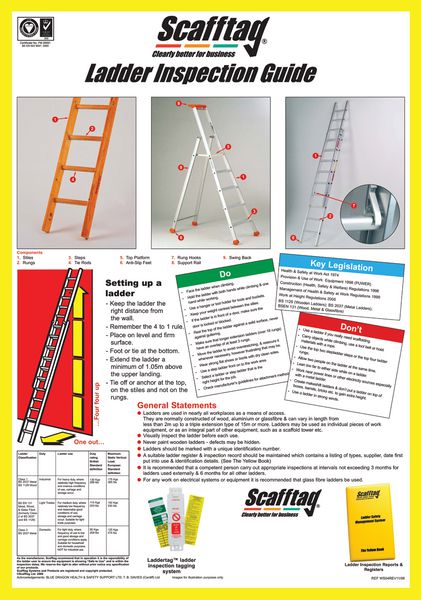

Scafftag® Ladder Inspection Guide Poster

£25.99Supplied in: Single -

Scafftag® Forkliftags® Kit

£33.99Supplied in: Single kit -

Scafftag® - SPECIAL OFFER

£72.99Supplied in: Single kit -

Podium Tag

From £3.99 To £42.99Supplied in: Single kit -

Scafftag® Microtag Inserts

From £19.99 To £103.99Supplied in: Pack of 20 -

Scafftag® Plant & Machinery Microtag® Kit

From £9.99 To £49.99Supplied in: Single kit -

Scafftag® Kit

From £5.99 To £66.99Supplied in: Single kit -

Scafftag® Plant & Machinery Microtag® Inserts

From £7.99 To £19.99Supplied in: Pack of 20 -

Scafftag® MEWP Replacement Inserts

£27.99Supplied in: Pack of 10 -

Scafftag® Nanotag Kits

£93.99Supplied in: Single kit -

Scafftag® MEWP Inspection Tags Kit

From £6.99 To £76.99Supplied in: Single kit -

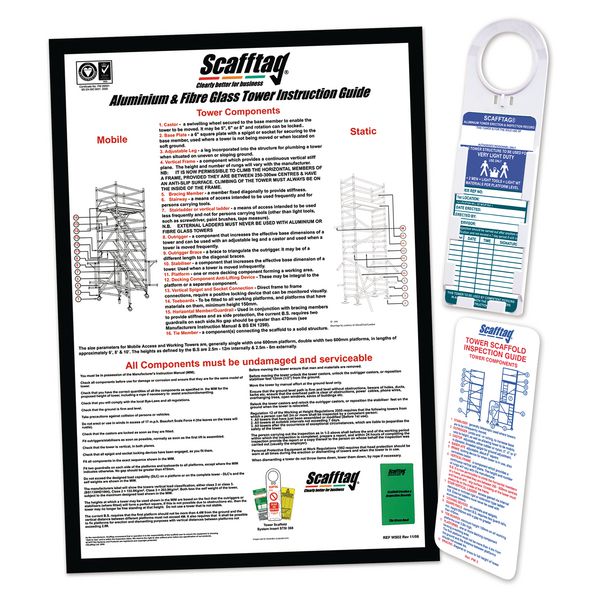

Scafftag® Towertag® Inspection Guide Poster

£23.99Supplied in: Single -

Scafftag® Nanotag™ Inserts - Next Test Date

£11.99Supplied in: Pack of 20 -

Stainless Steel Cable Ties

£41.99Supplied in: Pack of 40 -

Scafftag® Ladder Inspection Guide

£8.99Supplied in: Single -

Scafftag® Multitag LOLER Tag Kit

£45.99Supplied in: Single kit -

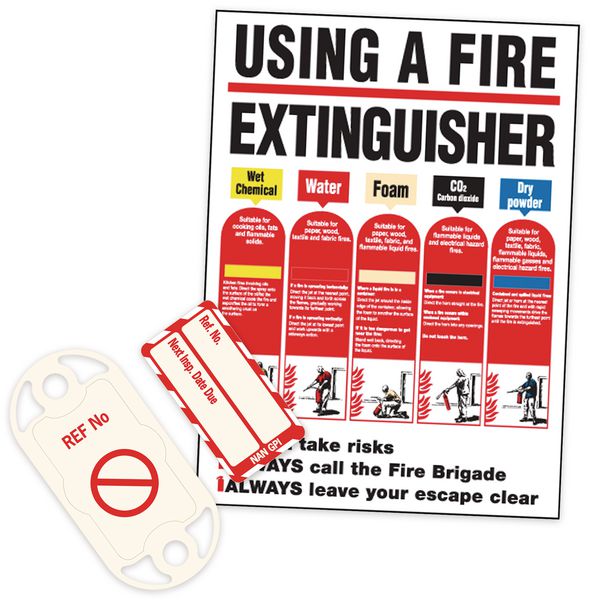

Scafftag® Fire Equipment Nanotag Kit

From £89.99 To £93.99Supplied in: Single kit -

Scafftag® Electrical Equipment Nanotag Kits

From £4.99 To £89.99Supplied in: Single kit -

Scafftag® Fencing Tag

£68.99Supplied in: Single kit -

Scafftag® Towertag® Tower Inspection Pocket Guide

£8.99Supplied in: Pack of 5 -

Scafftag® Electrical Equipment Tag Replacement Inserts

£12.99Supplied in: Pack of 20 -

Nanotag™ Split Ring

£3.99Supplied in: Pack of 10 -

Forkliftag & Safety Poster Kit

£46.99Supplied in: Single kit -

Scafftag® Nanotag™ Inserts - Next Inspection Date Due

£11.99Supplied in: Pack of 20 -

Laddertag & Work at Height Poster Kit

£57.99Supplied in: Single kit -

Towertag & Inspection Guide Kit

£79.99Supplied in: Single kit -

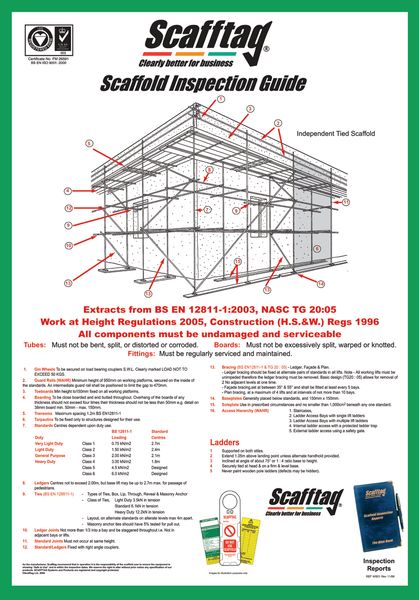

Scafftag® Scaffold System Guide Poster

£12.99Supplied in: Single -

Scafftag® Temporary Works Kit

£68.99Supplied in: Single kit -

Scafftag® Asbestos Tags - Asbestos Identified

£29.99Supplied in: Single kit -

Laddertag® Kit with Ladder Inspection Guide Poster

£103.99Supplied in: Single kit -

Scafftag Adhesive Pads

£5.99Supplied in: Pack of Ten -

Pack of 20 - Scafftag® Nanotag™ 'Next Test Date' Inserts

From £8.99 To £11.99Supplied in: Pack of 20 -

Scafftag® Scaffold Inspection Guide Poster

£8.99Supplied in: Single -

Microtag Plain Inserts

£9.99Supplied in: Pack of 20 -

Scafftag® Multi Tag Blank Inserts

From £8.99 To £17.99Supplied in: Pack of 10 -

Blank Scafftag® Inserts

£17.99Supplied in: Pack of 10 -

Scafftag® Unitag® Inserts - Blank

£9.99Supplied in: Pack of 20 -

Scafftag® Scaffold Status Inserts

£18.99Supplied in: Pack of 10 -

Scafftag® Nanotag™ - Blank Inserts

£9.99Supplied in: Pack of 20 -

Entrytag® Safety Tags

From £0.47 To £2.99Supplied in: Single -

Scafftag® MK2 Inserts

£16.99Supplied in: Pack of 10 -

Scafftag® Scaffold Prohibition Inserts

£16.99Supplied in: Pack of 10 -

Scafftag® MK2 Kit

£96.99Supplied in: Single kit -

Scafftag® Mark 2 Holders

£62.99Supplied in: Pack of 10 -

Scafftag® Entrytag Kit

£80.99Supplied in: Single kit -

Scafftag® Entrytag Holders

£62.99Supplied in: Pack of 10 -

Barcoded Microtag® Holders

£29.99Supplied in: Single kit -

Scafftag® Valvetag® Kit

£51.99Supplied in: Single kit -

Scafftag® Hoarding Kits

£72.99Supplied in: Single kit -

Scafftag® Asbestos Tags - Asbestos Free Area

£45.99Supplied in: Single kit -

Nanotag & Electrical Safety Poster Kit

£79.99Supplied in: Single kit -

Fire Equipment Nanotag & Extinguisher Sign Kit

£79.99Supplied in: Single kit -

Scafftag & Work at Height Poster Kit

£72.99Supplied in: Single kit -

Towertag & Work at Height Poster Sign Kit

£79.99Supplied in: Single kit -

Scafftag® Chemtag Kit

From £7.99 To £67.99Supplied in: Single kit -

Scafftag® Chemtag Replacement Holders

£62.99Supplied in: Pack of 10 -

Scafftag® Chemtag Replacement Inserts

£32.99Supplied in: Pack of 10 -

Scafftag® Fire Equipment Tag Replacement Inserts

£12.99Supplied in: Pack of 20 -

Scafftag® MEWP Replacement Holders

£62.99Supplied in: Pack of 10 -

Nanotag™ Kit

£51.99Supplied in: Single kit -

Scafftag® - Inspection Guide Poster

£23.99Supplied in: Single -

Scafftag® Inspection Pocket Guide

£8.99Supplied in: Pack of 5 -

Scafftag® Pen Clip Holder

£3.99Supplied in: Pack of 10 -

Scafftag® Colour-Coded Loading Inserts

From £10.89 To £49.99Supplied in: Pack of 10 -

Scafftag® Prohibition Inserts

From £8.99 To £39.99Supplied in: Pack of 50

Scafftag

Need help?

What is the scafftag procedure?

Creating a permanent information trail when carrying out the process of scaffold construction is made easy with scafftags. These tags are simple to install, maintain and use. The inserts provided allow you to keep track of inspections and modifications needed and the holders themselves have a bold warning message printed on them to use in the erecting and disassembly process.

What is the scafftag procedure?

Creating a permanent information trail when carrying out the process of scaffold construction is made easy with scafftags. These tags are simple to install, maintain and use. The inserts provided allow you to keep track of inspections and modifications needed and the holders themselves have a bold warning message printed on them to use in the erecting and disassembly process.

Scafftags are not just limited to use on scaffolds and other temporary structures. They are used on a wide range of industrial equipment and serve as an excellent method to keep track of inspections, giving workers vital safety information before using the equipment they are attached to.

Expert Information

Also discover:

Lockout tagout

Scafftag Procedure

The most popular use for scafftags is when assembling scaffolds. They serve as an easy reminder of the ongoing processes needed for the safe construction of the apparatus. In order to use scafftags effectively the following steps should be adhered to.

- Place the scafftag in a prominent place so that the warning is clear and visible to everyone

- When the scaffold has been erected place the insert with the construction inspection information face out, into the holder

- The scafftag can now be used by a competent person (a person that is a certified scaffolder) to record any inspections or modifications

- If inspections are required the insert is turned over to its other side which allows you to detail the date/time and signature of the persons responsible for carrying out the maintenance

- When the scaffold is no longer needed remove the insert and leave the holder in place so that its warning is once again visible to all employees

- Once the scaffold has been dismantled, the scafftag holder is removed and stored for further use

A simple process but one that could save lives, working at height is dangerous and if adequate safety information is not presented it could lead to accidents and even death.

The Complete Tagging System

There are many different types of scafftag to choose from, each with their own benefits and uses.One of the most used tagging solutions is Laddertags. They work in the same manner as the scaffold safety tags and firmly attach to ladders, giving you, the user, a clear indicator of whether the ladder can be used or not. These tags also give you information on ladder classes and a handy checklist to perform quick inspections before use.

Microtags are specially designed for use on power tools, these innovative tags have inserts which give many and varied details on the usage of the equipment they are attached to. They show simple information on the due dates for testing and inspection and more comprehensive safety information, such as the vibration created by equipment and the noise levels they generate, essential information for anyone using them. These tags are a must have for keeping your workers safe on the job.

For any sort of lifting equipment, forklift truck or heavy load vehicles use Unitags. These tags display safe working load, next test date and next inspection date. An unobtrusive round holder with simple slip in and out inserts these tags feature clear spaces to provide relevant safety information. They use steel or nylon strop to stay in place, as a safety feature to ensure that the tag cannot be removed unless by deliberate cutting.

Nanotags, as the name suggests are smaller than Microtags and Unitags but perform much the same function, due to their size they are ideal for use on hand held power tools but can also be used on larger equipment as long as they are displayed in a prominent position. They offer a way to relay vital safety information while being kept out of the way of the main body of the tool as to not impede its function in any way.

For use at the point of ingress for confined space entry, Entrytags are used with large oil drums or pipe that need inspection. When bought as a kit they come with inserts that detail inspection processes and general safety checks that should be performed. The addition of man in tank tags which can be attached via cable ties to the holder allow others to know instantly if any workers are actively carrying out maintenance or repair work.

Along with a large amount of options when it comes to the colour and information you wish to display in your tag holders we also supply blank tags to fit all of our holders. These allow you to create your own safety messages and display them how you see fit.

FAQ's

Where and when should I use scafftags?

The scafftag tagging system is extremely versatile and essential for any lockout tagout procedure, construction site or heavy machinery. They should always be present when constructing scaffold, when performing maintenance or repair on any heavy machinery, in many ways they will be the cornerstone of your lockout process.Why should I use scafftags?

As a rule it is better to prominently display safety information with hard wearing official tags and holders than to use easily perishable or poorly worded signage. Scafftag gives you all of the necessary and legally mandated information in concise and easily understood inserts.Did You Know, at Seton, we supply Scafftag Kits so if you can get everything you need to get started quickly, and keep your workplace safe.