-

Lockout Padlock & Tag Kits

£79.99Supplied in: Single kit -

ABUS Lockout Safety Padlocks

£110.99Supplied in: Pack of 6 -

Nylon Body Safety Padlocks

From £11.99 To £19.99Supplied in: Single -

Safety Padlocks

From £148.99 To £163.99Supplied in: Pack of Six -

Nylon SafeKey Padlock For Electrical Lockout

From £14.99 To £102.99Supplied in: Pack of 6 -

Compact Cable Padlocks

From £23.99 To £25.99Supplied in: Single -

Nylon SafeKey Padlock with steel shackle

From £17.99 To £102.99Supplied in: Pack of 3 -

Compact Cable Padlocks 6-Pack

From £131.99 To £144.99Supplied in: Pack of Six -

Safety Padlock & Tag Kit

£14.99Supplied in: Single kit -

Compact Safety Padlocks

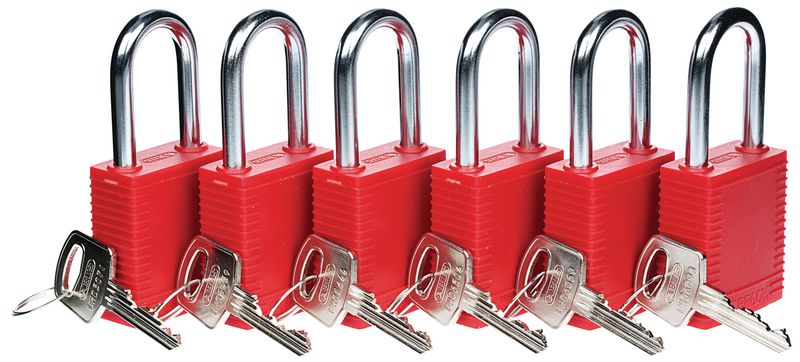

£110.99Supplied in: Pack of Six -

New

Ultra Compact Lock Box

From £15.55 To £230.79Supplied in: Single -

Aluminium SafeKey Padlocks

From £17.36 To £160.99Supplied in: Single -

High Performance Steel Padlocks

From £9.99 To £44.99Supplied in: Pack of 6 -

Coloured Aluminium Padlocks

From £155.99 To £170.99Supplied in: Pack of 6 -

Brass Padlocks

From £15.99 To £25.99Supplied in: Single -

Long Body Safety Padlocks

£160.99Supplied in: Pack of Six

Safety Padlocks

Need help?

Are you using the right padlock for the right job?

In order to properly secure your lockout equipment when in use and when being stored, you will want to use the best padlocks available to you. They are simple security devices that, as part of an effective lockout programme, ensure that all devices and equipment remains where it needs to without any unauthorised access possible.

Are you using the right padlock for the right job?

In order to properly secure your lockout equipment when in use and when being stored, you will want to use the best padlocks available to you. They are simple security devices that, as part of an effective lockout programme, ensure that all devices and equipment remains where it needs to without any unauthorised access possible.

There are many things to consider when choosing the type and material of padlock that you will require, security is one of the most important elements of a successful lockout process. Our padlocks offer a wealth of options, guaranteeing comprehensive solutions for your safety padlock needs.

Also discover:

Lockout tagout

Lockout Padlocks: Buying Guide

Since the main reason for lockout process existing is the isolation of energy for heavy industrial machinery, choosing the right padlock to secure devices for the task is paramount. There are many options when it comes to selecting the right safety padlock for the right device. We have padlocks that are supplied in varied colours that enable you to give individuals padlocks that are unique to them. This allows you to track who is using lockout devices, who has locked out machinery and therefore, those responsible for carrying out the work.

One of the things that you will most likely have to consider is the material of the body of the padlock. In order to ensure that you will get maximal use out of these devices, we supply them in a range of materials so that you will have a padlock to suit any situation.

Our non-conductive padlocks are made from tough, hardwearing material that is ideal to be used in areas with a high risk of electrical discharge. Many of our lockout devices are designed to be used on circuit breakers, these small and ingenious pieces of equipment are very simple to install, as are all of our electrical lockout devices. Once in place it is of the utmost importance to ensure that they remain secure, it goes without saying that by using a padlock constructed of a non-conductive material in this instance, you are taking adequate safety precautions.

Whenever you apply these devices and locks to lockout an electrical power source, even though they are made of non-conductive material, it would be wise to also use specialised safety gloves that will protect the user from any accidental shocks that could occur when working around such equipment as these types of injury are all too common.

The padlocks that are used most regularly are made of metal, they give you the best security and make for the best option when securing heavy machinery equipment, lockboxes and lockout cabinets. We have many different materials to choose from within this range. The majority of these are made from aluminium and steel, both are extremely hard wearing and corrosion resistant, so are perfect for security applications, internally and externally.

Different Types of Locks Available

One of the most important things to consider other than the material of the padlock is the type of key and lock you wish to use. There are a few different combinations that can be used, each with their own advantages.- Keyed alike padlocks are usually supplied in packs of six, these padlocks have one key that opens all of the padlocks. This will be useful in a lockout programme when there is one authorised person that is managing the entire usage of the padlocks to secure lockout equipment.

- Keyed differently padlocks, as the name suggests are supplied with keys individual to each padlock. These are great for use in lockout procedures as they allow multiple people to work on a machine and each add their own padlock to hasps used to secure the devices. Our colour coded padlocks are ideal to use as a keyed differently option, creating a system by which each authorised person has their own padlock.

- Master keyed padlocks are in some ways a combination of the other two, supplied as either keyed alike or differently but they also come with a master key that open all of the padlocks. These are good for when keys are lost or in the case of combination padlocks, if the combination is forgotten it can be reset using the master key. The master key should be held in a secure location with only authorised personnel given access.