-

Meter Seals

From £99.99 To £249.99Supplied in: Pack of 250 -

Blank Multi-Purpose Tag Holder/Slider Safety Message Tags

£61.99Supplied in: Pack of 10 -

Pack of 5 - Brady Write On Safety Tags With Nylon Tags

From £9.99 To £10.83Supplied in: Pack of 5 -

Joint Assembly Tags

£20.99Supplied in: Pack of 10 -

Tie-On Maintenance Status Tags

From £22.99 To £23.99Supplied in: Pack of 10 -

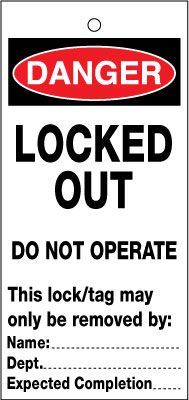

Locked Out Do Not Operate Lockout Safety Tags

£16.99Supplied in: Single -

Lockout Safety Tags - Do Not Operate (pack of 10)

£16.99Supplied in: Pack of 10 -

Two-Part Perforated Tags - Do Not Operate

£25.99Supplied in: Packs of 25 -

Lockout Danger Tags

From £15.99 To £26.89Supplied in: Pack of 10 -

Multi-Purpose Tag Holder and Tag Kits

From £39.99 To £79.99Supplied in: Single kit -

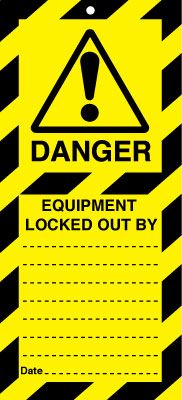

Padlock Tag – Equipment Locked Out

£15.99Supplied in: Pack of 10 -

Photo Lockout Tag - Do Not Operate

From £27.99 To £60.99Supplied in: Pack of 10 -

Safety Information Tags

From £28.99 To £31.99Supplied in: Pack of 10 -

Tag Holder

£29.99Supplied in: Single -

Safety Tag System Equipment Inspection Record

£19.99Supplied in: Pack of 20 -

Maintenance Tags Ladder Inspection Record

£19.99Supplied in: Pack of 20 -

Safety Message Tags - Safe To/Do Not Use

£17.99Supplied in: Pack of 20 -

Safety Management Tag System - Safe To/Do Not Operate

£19.99Supplied in: Pack of 20 -

Safety Message Tags - Valve Open/Closed

£19.99Supplied in: Pack of 20 -

Self-Adhesive Labels Machinery Locked Out

£60.99Supplied in: Pack of 100 -

Maintenance Tags Valve Inspection Record

£19.99Supplied in: Pack of 20 -

Mini Lockout Tags

£37.99Supplied in: Pack of 25 -

Lockout Warning Tags

From £15.99 To £31.09Supplied in: Pack of 10 -

Safety Tag System Scaffold Tower Inspection Record

£19.99Supplied in: Pack of 20 -

Photo Lockout Tag – My Life Is On The Line

£33.99Supplied in: Pack of 10 -

Lockout Safety Tags - Equipment Locked Out By

From £14.99 To £16.99Supplied in: Pack of 10 -

High-Visibility Lockout Tags

£14.99Supplied in: Pack of 10 -

Lockout Safety Tags - Do Not Operate

From £14.99 To £16.99Supplied in: Pack of 10 -

Padlock Tag – Do Not Operate

£3.99Supplied in: Single -

Lockout Mini Tags

£49.99Supplied in: Pack of 50 -

Two Part Perforated Tags

£59.99Supplied in: Packs of 25 -

Safety Tag System Self-Adhesive Labels Equipment Fault

£60.99Supplied in: Single -

Special Instructions/Remarks Material Control Tags

£13.49Supplied in: Pack of 10 tags -

Safety Tag System Do Not Switch Power On Labels

£60.99Supplied in: Pack of 100 -

Promotion

Pack of 100 - Durable Nylon Protective Security Ties

From £7.99 To £19.99

From £7.99 To £15.99

Supplied in: Pack of 100 -

Padlock Tag – Equipment Lockout a Life

£15.99Supplied in: Pack of 10 -

Safety Tag System Fork Lift Inspection Record

£19.99Supplied in: Pack of 20 -

Photo Lockout Tag – Energy Source Locked Out

£33.99Supplied in: Pack of 10 -

Equipment Locked Out To Protect Workers Lockout Tags

From £14.99 To £16.99Supplied in: Single -

Flange Tags

£20.99Supplied in: Pack of 10 -

Lockout Maintenance Tags

From £15.99 To £26.89Supplied in: Pack of 10 -

Structural Tie Test Tag

£53.99Supplied in: Pack of 50 -

Structural Tie Warning Tags

£53.99Supplied in: Pack of 50 -

Heatex™ Cable Markers

£879.99Supplied in: Roll of 500 Markers -

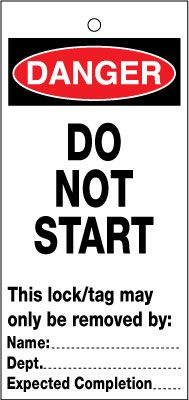

Lockout Safety Tags - Do Not Start (pack of 10)

£16.99Supplied in: Pack of 10 -

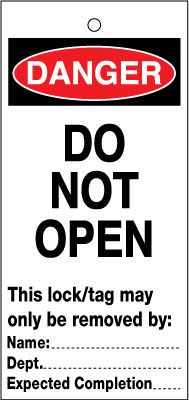

Lockout Safety Tags - Do Not Open

£16.99Supplied in: Pack of 10 -

Lockout Safety Tags - Danger a Life is on the Line

£14.99Supplied in: Single -

Photo Lockout Tag – To Be Removed By

£33.99Supplied in: Pack of 10 -

Lockout Safety Tags - Lock Out Before Operation

From £14.99 To £16.99Supplied in: Single -

Lock Out Before Attempting Any Repairs Lockout Tags

From £14.99 To £16.99Supplied in: Single -

Pack of 10 Write On Lockout Padlock Tag Covers 100x50mm

£17.99Supplied in: Pack of 10 -

Lockout Safety Tags - This Tag & Lock to be Removed Only by Person Shown

From £14.99 To £16.99Supplied in: Pack of 10 -

Safety Management Tag System - Starter Kit

From £129.99 To £250.99Supplied in: Single kit

Lockout Tags

Need help?

What is an effective tagout procedure?

A vital part of any lockout process is displaying information, this is important to keep those around you safe while working on potentially dangerous machinery. A simple warning tag attached to lockout devices will serve as a reminder and instant visual signifier to take care when working around de-energised machinery.

What is an effective tagout procedure?

A vital part of any lockout process is displaying information, this is important to keep those around you safe while working on potentially dangerous machinery. A simple warning tag attached to lockout devices will serve as a reminder and instant visual signifier to take care when working around de-energised machinery.

With our wide range of tags you will be able to create a lockout procedure with a comprehensive tagging system, which will ensure priority information is prominently displayed.

Effective Tagout Procedure

Via a tag attached to your lockout devices, you will be able to ensure that there is a point of reference that clearly indicates the actions others should take in relation to locked out machinery and also comply with health and safety legislation.

When following your lockout procedure, the step of attaching important safety information is done as part of using the lockout devices themselves. The information is represented by using a simple tagging system that employs cable ties applied around the safety padlock itself.

It is best as part of the risk assessment to determine the types of lockout device you need, that you consider the warning labels and safety tags you will need to compliment them and the vital information you must display.

Many of the tags are used as part of a tagging system to simply identify machinery. These are ideal to inform employees of active energy sources and help when it comes time to perform maintenance and repair. Allowing for the easy identification of machinery.

There are also many ways of attaching tags to equipment, the most common is by using cable ties (in this instance we would recommend the most heavy duty tie that you can use, as these tags will invariably be used in industrial areas) but we also supply tags that are made of metals such as brass to attach to valve pipes with metal chains and clip that cannot be removed easily, this is another way to permanently identify a machine, rather than as part of a temporary lockout procedure.

A Tag for Every Situation

We offer a range of tags designed for specific uses, for ease we have organized them into categories to showcase each of these functions.- Safety tags encompass our identification tagging systems, from metal tags to simple number and letter combinations that allow you to create your own identification system that should be detailed in your lockout procedure paperwork. These tags offer simple messages in bold lettering, using highly recognizable symbols to convey safety messages.

- Valve tags comprise all of our metal tagging systems, this is simply because valves and pipes tend to carry heated steam or gas, sometimes noxious materials, and the tags that are attached to them cannot be made of easily perishable materials. Our other plastic tags would not be able to withstand use in this sort of environment, so it is an absolute must that you use aluminium or brass tags, they come supplied with numbers and letters or can be customised to your need, with any combination of symbols you require.

- Danger tags are overt messages to warn of the danger of not following procedures with de-energised machinery and can save lives. These tags have clear and concise text and imagery precisely to do just that. As with many tags designed for use in lockout procedures they also have room for other details, allowing you to input the name of the person responsible for locking out the equipment, creating a clear chain of accountability.

- Inspection tags are designed to create a record of the people that have been tasked with the maintenance and service of equipment. When attached to lockout devices, they serve as a way to stay up to date with the status of repairs and as a reminder of the last time machinery was inspected. Use these after lockout processes have been followed as an easy way to remind those responsible to carry out inspections regularly.

- Maintenance tags are to be used whenever a machine needs servicing, these tags aid in informing employees that work is in progress. With bold messages and lots of space to fill in inspection dates and times, they will enable you to create a comprehensive record of completed maintenance.