-

Lockout Padlock & Tag Kits

£79.99Supplied in: Single kit -

ABUS Lockout Safety Padlocks

£110.99Supplied in: Pack of 6 -

Nylon Body Safety Padlocks

From £11.99 To £19.99Supplied in: Single -

Nylon SafeKey Padlock For Electrical Lockout

From £14.99 To £102.99Supplied in: Pack of 6 -

Compact Cable Padlocks

From £23.99 To £25.99Supplied in: Single -

Compact Cable Padlocks 6-Pack

From £131.99 To £144.99Supplied in: Pack of Six -

Safety Padlock & Tag Kit

£14.99Supplied in: Single kit -

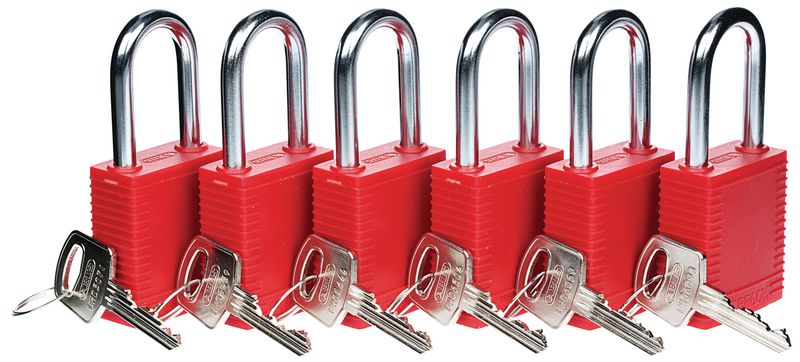

Compact Safety Padlocks

£110.99Supplied in: Pack of Six -

New

Ultra Compact Lock Box

From £15.55 To £230.79Supplied in: Single -

Long Body Safety Padlocks

£160.99Supplied in: Pack of Six

Plastic Padlocks

Need help?

How Can Plastic Padlocks Increase Safety?

Staying compliant with health and safety legislation is important, especially in workplaces that utilise heavy industrial machinery. Our lockout tagout range allows you to effectively isolate the power of these machines to effect repairs and vital maintenance.

How Can Plastic Padlocks Increase Safety?

Staying compliant with health and safety legislation is important, especially in workplaces that utilise heavy industrial machinery. Our lockout tagout range allows you to effectively isolate the power of these machines to effect repairs and vital maintenance.

Securing your lockout devices in place will ensure they remain free from tampering and unauthorised access. In order to isolate electrical machinery it is best to consider a non-conductive security option, wearing the appropriate PPE and taking all relevant precautions is essential. Our range of non-conductive plastic padlocks will deliver security as well as effective protection from electrical hazards.

Also discover:

Lockout tagout

Plastic Safety Padlocks: Buying Guide

When employing any lockout procedure, security of the devices used to isolate the energy of machinery is a vital step in this process. However, many of the isolation points for machines will be electrically charged with some even remaining so after the power has been turned off. When attaching any circuit breaker lockout devices to breaker switches, for instance, it is best to use an insulation PPE glove but for the general safety of everyone at your site, using a non-conductive padlock will avoid accidents from casual inspection of the devices installed.

In order to make the padlock electrically non-conductive and still a viable security measure the main body of the padlocks are made of Nylon, this has several advantages as it makes the padlock corrosion and chemical resistant. So not only will they help workers avoid unnecessary injuries from electrical hazards but are in fact very hard wearing and ideal for use in harsh industrial environments.

For locking out electrical power points, you will sometimes require many people to be working on one piece of machinery at once. In these instances we advise using a hasp which allows several padlocks to secure the lockout device in question, creating a clear chain of responsibility as the machinery can only be released from the isolating equipment once all work is completed. We supply a range of non-conductive plastic hasps which are ideal for use in these situations, when combined with our padlocks you will have everything you need to effectively isolate electrical machinery safely.

Securing Lockout Devices is an Essential Part of Lockout Procedures

Due to this being such a vital part of the lockout process we have created a range of ways to ensure you have all of the equipment necessary to complete such processes with the minimum of fuss. We supply a number of ways to get all of the materials needed to create your own lockout procedure with ease.With our range of electrical lockout kits you will be supplied with all that you need to isolate electrical machinery, they come in a wide range of options, some created for small businesses that will not have multiple machines being locked out at once and other larger kits for larger sites. Each come with a range of devices, padlocks, hasps and tags and are a great way to be prepared for maintenance and repair situations on hazardous electrical machinery.

Within our plastic padlocks category we have created an offering that tailors for most uses and situations, featuring individual padlocks to augment a pre-existing lockout solution and the ability to buy multiple packs for easily bolstering lockout processes at your workplace. The plastic padlocks have been designed and constructed in such a way that they will offer effective security for any lockout device or lockout box, keeping equipment safe when not in use.

Combined with our metal padlocks, all areas are covered; all lockout security eventualities can be planned for. When it comes to ensuring the safety of workers and complying with relevant safety measures our padlocks, along with our extensive range of lockout equipment, will provide all that you will need to keep employees safe while maintenance and repair work is completed.