-

Promotion

Large Steel Drum Funnel For Flammables

£349.99

£319.99

Supplied in: Single -

Promotion

Syphon Pumps

From £14.99 To £24.99

From £11.99 To £20.99

Supplied in: Single -

Promotion

Large Bore Threaded Tap - Polyethylene

£24.99

£20.99

Supplied in: Single -

Promotion

Romold Multi Size Drum Cradle

£129.99

£109.99

Supplied in: Single -

Promotion

Barrel Adapters

£9.99

£8.99

Supplied in: Single -

Promotion

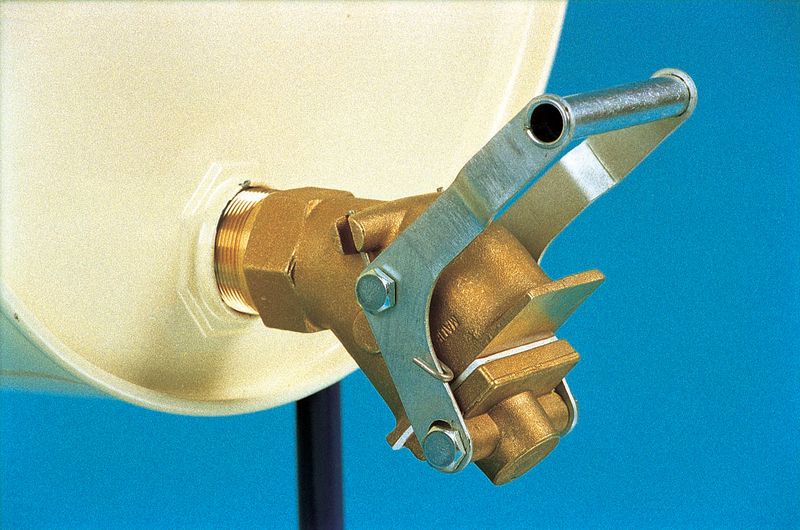

Barrel Tap - Steel Drum

£149.99

£99.99

Supplied in: Single -

304 Stainless Steel & Teflon® Rotary Pump

£499.99Supplied in: Single -

Promotion

Brass Drum Tap

£269.99

£249.99

Supplied in: Single -

Promotion

Enpac Poly-Drum Funnel

£159.99

£129.99

Supplied in: Single -

Promotion

Brass Safety Drum Faucet

£99.99

£64.99

Supplied in: Single -

Promotion

Enpac Poly-Drum Funnel Cover

£189.99

£139.99

Supplied in: Single -

Promotion

Self-Closing Stainless Steel Barrel Tap

£99.99

£94.99

Supplied in: Single

Drum Pumps, Taps & Accessories

When storing hazardous liquids in drums, one of the biggest questions you will face is how to safely decant small amounts for day to day tasks. Once you have identified a suitable chemical container you will need to dispense the liquid into it in a secure and controlled way. Manually pouring the contents of a drum should not be attempted and large mechanical devices for this purpose are often impractical. This is where apparatus such as barrel taps or syphon pumps can make a big difference. Seton has a range of tried and tested options available.

Expert Information

Safe Drum Dispensing

Once you have carried out a COSHH risk assessment you will have a plan for how chemicals are stored and what steps should be taken to move them within your location. A critical part of ensuring regulations are met will also be working out what apparatus is required for dispensing liquids, however it can easily be overlooked.

Drums, barrels and other large containers are heavy, bulky and not easy to move so it is far safer to decant the contents into smaller receptacles when performing everyday tasks. Trying to do this by tipping the drum to pour its contents is not a good idea. Not only do you run the risk of sustaining handling related injuries such as musculoskeletal disorders, the chance of spills is increased. Your risk assessment will have determined if there is a great enough need to require large mechanical handling equipment for pouring, but often machinery will be deemed unnecessary.

A less labour intensive way of portioning out the contents of a drum or barrel will be to use a tap or pump which can be fitted to its opening in a matter of moments.

Drum Dispensing Equipment

Seton can provide a wide range of dispensing solutions, with options suitable for all liquid types available.

Stainless steel rotary pumps are incredibly easy to fit and use and can be supplied in a regular version for general chemicals and solvents or a specialised variety suitable for aggressive chemicals. Pumps can be used in an upright position eliminating the need for any kind of tipping or laying of the drum.

For barrels and other containers simple taps can be used. The steel drum barrel tap offers incredible control and allows you to tailor the flow of liquids as required. Ensuring taps are fitted securely to the barrel is of prime importance. To guarantee a snug fit a selection of barrel adaptors and “O” rings can be purchased.

Once work is completed a funnel can be used to return liquids to the drum with a minimum amount of fuss.

Staff should be trained on how to safely connect any dispensing apparatus and be aware of what to do in the event of an accident.

Once a tap or pump has been fitted, it is a good idea to perform a quick leak test to be sure of a good connection before work commences. A tray should be placed under taps to collect any drips and a well-stocked supply of absorbent materials must be kept nearby in case of emergency.