-

Spill Deck

£134.99Supplied in: Single kit -

Enpac Spill Pallets

From £260.99 To £382.99Supplied in: Single -

Enpac 2 & 4 Drum Spill Pallets

From £269.99 To £299.99Supplied in: Single -

Promotion

Spill Trays

From £149.99 To £199.99

From £89.99 To £169.99

Supplied in: Single -

Drum Store - Economy

£4,299.99Supplied in: Single kit -

Promotion

Economy IBC Sump Pallets

From £999.99 To £1,499.99

From £899.99 To £1,499.99

Supplied in: Single -

Promotion

Romold Spill Trays with Grid

From £51.99 To £89.99

From £44.99 To £84.99

Supplied in: Single -

Romold Spill Tray For 25 Litre Cans

£219.99Supplied in: Single -

Romold Inline Bund Flooring

£469.99Supplied in: Single -

Promotion

Hardcover Spill Pallets

From £1,499.99 To £2,499.99

From £1,499.99 To £2,399.99

Supplied in: Single kit -

Promotion

Galvanised Drip Trays

£69.99

£64.99

Supplied in: Single -

Promotion

Enpac Drum Workstations

From £329.99 To £899.99

From £299.99 To £899.99

Supplied in: Single -

Promotion

Forklift Drum Clamps

From £379.99 To £499.99

From £329.99 To £499.99

Supplied in: Single -

Romold Contained Spill Trays

From £89.99 To £199.99Supplied in: Single -

Promotion

Drum Truck with Rear Wheels

£399.99

£369.99

Supplied in: Single -

Promotion

Romold Spill Trays

From £24.99 To £54.99

From £24.99 To £49.99

Supplied in: Single -

Promotion

Galvanised Steel Spill Pallet

From £699.99 To £899.99

From £649.99 To £849.99

Supplied in: Single -

Promotion

Drum Truck

£299.99

£279.99

Supplied in: Single -

Promotion

Romold Low Profile Spill Trays

From £24.99 To £34.99Supplied in: Single -

Romold Pouring Spill Tray

£16.99Supplied in: Single -

Promotion

Armorgard DrumBank IBC Containter Storage - Grey

£3,999.99

£3,799.99

Supplied in: Single -

Promotion

Enpac Poly-Dolly

£1,299.99

£1,099.99

Supplied in: Single -

Promotion

DrumBank 2 & 4 Drum COSHH Storage - Blue

From £2,299.99 To £2,999.99

From £2,199.99 To £2,873.41

Supplied in: Single -

Promotion

Enpac Polyethylene Spill Scooter - 204 kg Load Capacity

£499.99

£449.99

Supplied in: Single -

Promotion

Large Steel Drum Funnel For Flammables

£349.99

£319.99

Supplied in: Single -

Promotion

Syphon Pumps

From £14.99 To £24.99

From £11.99 To £20.99

Supplied in: Single -

Promotion

IBC Galvanised Steel Spill Pallet

From £1,399.99 To £1,699.99

From £1,299.99 To £1,699.99

Supplied in: Single -

Promotion

DrumBank 2 & 4 Drum COSHH Storage with Shelf - Charcoal

£3,299.99

£3,199.99

Supplied in: Single -

Promotion

Enpac Poly Spill Cart

£1,299.99

£1,199.99

Supplied in: Single -

Promotion

Large Bore Threaded Tap - Polyethylene

£24.99

£20.99

Supplied in: Single -

Enpac Hardcover Spill Pallet Ramp

£549.99Supplied in: Single -

Promotion

Steel Blue Sump Flooring Chemical-Resistant Materials

From £1,399.99 To £2,999.99Supplied in: Single -

Promotion

Romold Recycled Spill Pallet

From £249.99 To £349.99

From £219.99 To £319.99

Supplied in: Single -

Promotion

Romold Multi Size Drum Cradle

£129.99

£109.99

Supplied in: Single -

Enpac Multi-Purpose Ramp

£349.99Supplied in: Single -

Promotion

Barrel Adapters

£9.99

£8.99

Supplied in: Single -

Promotion

Enpac Single Drum Spill Trays

From £159.99 To £249.99

From £129.99 To £199.99

Supplied in: Single -

Promotion

UN Rated Poly Overpack

From £159.99 To £169.99

From £129.99 To £139.99

Supplied in: Single -

Promotion

Barrel Tap - Steel Drum

£149.99

£99.99

Supplied in: Single -

304 Stainless Steel & Teflon® Rotary Pump

£499.99Supplied in: Single -

Promotion

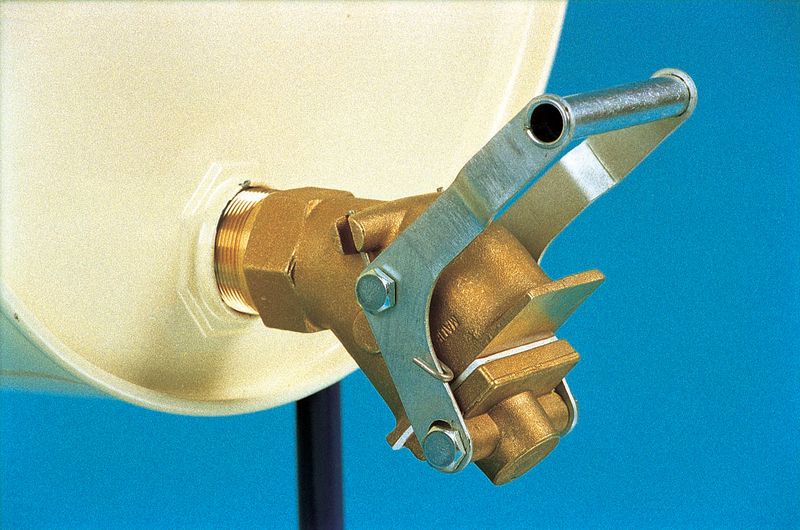

Brass Drum Tap

£269.99

£249.99

Supplied in: Single -

Promotion

Enpac Poly-Drum Funnel

£159.99

£129.99

Supplied in: Single -

Promotion

Brass Safety Drum Faucet

£99.99

£64.99

Supplied in: Single -

Promotion

Enpac Poly-Drum Funnel Cover

£189.99

£139.99

Supplied in: Single -

Promotion

Self-Closing Stainless Steel Barrel Tap

£99.99

£94.99

Supplied in: Single -

Promotion

Bunded Steel Spill Flooring

From £1,199.99 To £1,799.99

From £1,099.99 To £1,799.99

Supplied in: Single -

Promotion

Premier IBC Sump Pallet

£2,699.99

£2,499.99

Supplied in: Single kit -

Promotion

Enpac Poly-Lab Tray

£159.99

£139.99

Supplied in: Single -

Promotion

Fully Enclosed Drum Stores

From £2,599.99 To £4,499.99

From £2,599.99 To £4,399.99

Supplied in: Single -

Sump Flooring - Optional Ramp

£549.99Supplied in: Single

Drum Handling

Need help?

Handle drums safely with the correct equipment

Get 5* COSHH Compliant Drum Handling Equipment for Less

Handle drums safely with the correct equipment

Get 5* COSHH Compliant Drum Handling Equipment for Less

From trolleys, cradles and lifters we have all the drum handling equipment you need. Looking for COSHH compliant drum storage and spill containment? Our assortment of spill trays and bund pallets provide a safe and legal solution, while our collection of taps, valve and pumps make dispensing and decanting a breeze.

Drums that contain oils or other hazardous substances pose several risks. Drums and IBCs are often heavy and difficult to move while the contents may be harmful or even flammable. This means, under COSHH regulations, having the correct procedures and provisions for their handling and storage are vital.

Expert Information

Also discover:

COSHHGas cylinder safetyChemical storageDrum TrolleysDrum PalletsDrum Storage Syphon pump

Safe Drum Handling: Buying Guide

The importance of risk assessment for liquid storage containers and drums

A thorough risk assessment is the first step in minimising risks when working with drums and harmful materials. The HSE points out that it’s prescribed by the Control of Substances Hazardous to Health (COSHH) Regulations to help you identify dangers and implement risk-management measures. Your risk assessment indicates what you need and what you must do to keep your workplace safe.

The law requires you to adequately control exposure to materials in the workplace that cause ill health. This is the Control of Substances Hazardous to Health Regulations (COSHH) and means:

- identifying which harmful substances may be present in the workplace

- deciding how workers might be exposed to them and be harmed

- looking at what measures you have in place to prevent this harm and deciding whether you are doing enough

- providing information, instruction and training

- in appropriate cases, providing health surveillance

Harmful Substances

HSE.gov.uk

What Is Drum Handling?

Drum handling refers to:

- Any measures taken to safely store harmful substances

- Methods used to transport drums from one place to another

- Equipment used to lift and transport drums

- PPE needed for safe handling

- Devices used to safely empty and fill barrels

Essentially, everything from a drum truck and spill pallet to a syphon pump and drum tap have to do with drum handling. It’s therefore vital to train employees regarding safety precautions and barrel handling equipment.

STORAGE

Drum handling includes the specialist equipment and practices deployed to safely store harmful substances.

TRANSPORT

Drum handling encompasses purpose-built devices and techniques for moving hazardous substances around your premises.

DECANTING

Drum handling covers devices used for decanting and dispensing substances hazardous to health, such as taps, pumps and faucets.

A specialist storage facility is the cornerstone of effective drum handling. Whether large or small, these containers or drum stores are the place where safety starts and ends. For example, Seton’s fully enclosed drum stores have:

- Sumps on all models, featuring a built-in drain plug

- Lockable doors with three-point locking to prevent tampering

- One or two doors to meet your needs

When planning your drum storage, keep secondary containment in mind. Leaks or spills can lead to contact between different liquids, creating added risks. We recommend our drum storage hut in this instance.

- It’s a secure, outdoor storage unit for hazardous materials.

- The tough polyethylene construction resists corrosion and won’t fade in sunlight.

- It holds up to eight drums and has ample space to prevent leaks and spills.

If your heavy-duty environment demands an infallible storage solution, our top-of-the-range IBC container is ideal. This rugged storage unit is the ultimate in spill control and drum storage. It features:

- 1,100-litre sump capacity

- Fire resistance of up to 30 minutes so that you have time to deal with an emergency

- A secure five-lever deadlock to prevent unauthorised tampering

Drum Movement

Needless to say, the movement of drums containing hazardous substances is risky. Use specialist drum handling solutions to prevent things such as spills and leaks.

Seton’s health and safety experts sourced only the best purpose-built trucks and carts and drum pallets and trays. To further reduce the chance of accidents, also consider added safety measures such as built-in sumps and well liners.

Seton’s cost-effective drum truck not only improves safety while moving drums, but also has the muscle to handle 210-litre drums. The drum truck:

- Is made from robust powder-coated steel for a long-lasting service life

- Comes with ergonomic handles for easy control

- Has an engaging hook for handling open-top and tight-head drums

Another handy movement option is our drum truck with rear wheels for easier manoeuvring and balancing. This workhorse handles loads of up to 280kg without breaking a sweat.

We would recommend taking a look at our spill pallet ramp. This portable innovation helps with the movement and placement of drums. The:

- 100% polyethylene construction is durable and robust to handle heavy loads

- Ribbed, non-slip surface helps prevent accidents

Safe Filling And Emptying Of Drums

Use the right accessories to safely fill and empty drums. Seton stocks the best apparatus for emptying or filling drums, such as funnels or chemical pumps.

We have different variations suited for every situation, such as our large steel drum funnel for flammable liquids. It:

- Is fitted with a brass flame arrester that absorbs and dissipates heat

- Prevents external ignition sources, such as sparks, from reaching the flammable contents

- Complies with EPA and OSHA regulations and is FM TUV approved

Seton’s funnel selection also features a hinged poly-drum funnel cover for 205-litre drums. This nifty gadget is lockable to keep out contaminants and prevent tampering.

Also, check out our on-point selection of drum taps. Seton’s experts gathered everything from barrel taps and rotary pumps to self-closing faucets with extension spouts to make your job safer and easier.

Spill control is a must during any stage of drum handling. A spill tray can be sized to fit several small containers or a single large one. In case of an accident, keep your spill barriers, drain covers and sorbents close to the relevant area.

Getting Your Employees Drum Handling Ready

Train employees in the use of drum handling equipment, whether it is a simple funnel or a more complicated drum lifter. For example, a drum trolley or barrel lifter may have added clamps that need to be fastened at certain stages of the lifting process.

Ensure that your employees know the different types of hazards and how to identify them using signage and training equipment. Dealing directly with hazardous substances often requires the use of personal protective equipment (PPE).

FAQ

How Do I Determine How Much Drum Storage I Need?

Strict government rules outline what the capacity of any sump or bund on your site should be. Matching the amount you have to store to these regulations sets you on the right track.

How Do I Know That A Drum Is Safe To Work With?

Safety-approved drums carry the UN mark. Additionally, ensure that the barrel is not damaged and shows no signs of bulging.

UN mark is a universal / international system created by the United Nations, which is meant for the classification, packaging, marking and labelling of dangerous goods, in order to transport it safely (by road, rail, sea and air). Testing are required to be carried out, before a UN certification mark can be issued. The packaging must meet or exceed minimum standards of performance before it can be used.

UN Marking Certification Scheme for Packaging

TUV Sud

How Do I Safely Move A Drum?

Use the right tool – such as barrel lifting equipment or a drum lifter and tilter – to move and store barrels. You can move some drums with a manual drum lifter, while others require a drum lifter for a forklift, such as a forklift barrel grabber.

What Is An IBC (Intermediate Bulk Container) Spill Pallet?

It’s a drainable platform underneath a drum that contains leaks and spills.

How Does A Spill Pallet Work?

A spill pallet features a grate and built-in sump capacity to contain spills.Take a look at the below video highlighting the features of our spill deck products.

Whether it’s a drum lifter trolley, forklift drum lifter, spill pallet, drum tap or safety ramp, we have everything you need. Browse our extensive range of drum handling equipment to boost your workplace safety.